What Is The Purpose Of Walk-in Chambers?

Walk-in test chambers are best used for preparing and conditioning samples.

Adjusting the temperature and humidity of items or materials. In order to learn more about a product's quality over time, the aging of samples and materials is employed to speed the process.

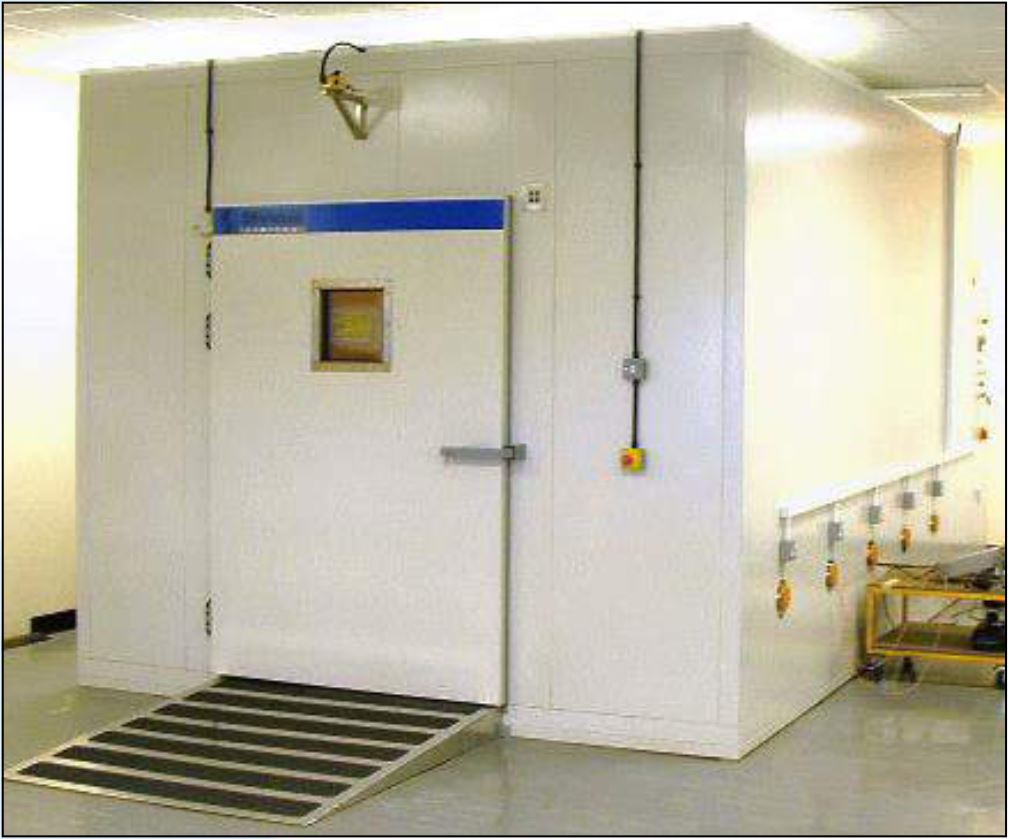

It can be as little as a box that sits on a bench top or as large as a room for testing massive products or a large number of commodities simultaneously. From -60 to 90 degrees Celsius, the temperature ranges from 20 to 90 percent relative humidity. A temperature-humidity walk-in chamber can be used for product testing when constant climatic conditions (temperature and/or humidity) are necessary.

Using a walk-in test chamber, engineers may mimic the impact of various temperature and humidity conditions on various products and materials, such as telecommunications equipment or photovoltaic solar panels.

- Sample aging aided by temperature and humidity

- Getting the samples ready

- A weather and water tightness test was performed.

- Once the pharmaceuticals have been completed and shipped across the tropics, they are tested

- Putting up a prototype

- Using a computer for testing

- Product life expectancy

The Environmental Assess Chamber is used to test the heat, cold, dryness, and humidity-resistant characteristics. Quality control and research and development in a wide range of sectors are the primary functions of this device.

Samples are kept in the chamber for a set duration of time, temperature, and humidity level to study the aging qualities of the sample. Experiments can be set up to simulate an ever-changing environment, or they can employ the user interface to simulate a steady state of stability. Faster testing in an agile production environment means a better bottom line.