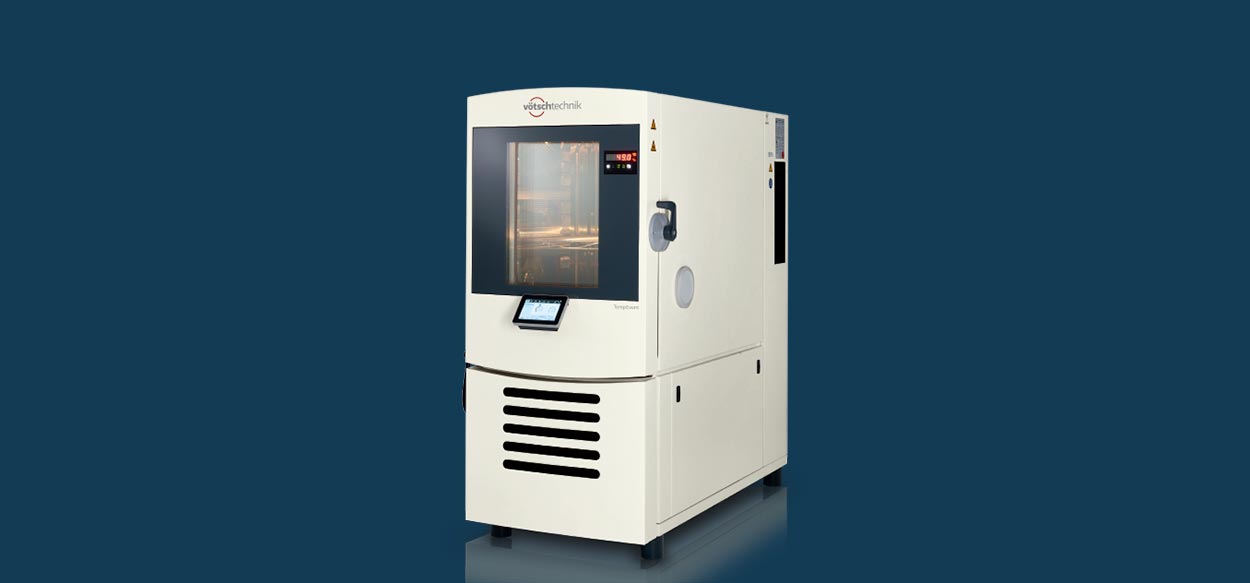

Environmental Test Chambers Being Installed

Most laboratories prioritize variables such as functionality, performance, and cost-effectiveness when acquiring a new environmental test chamber. However, few of them take installation requirements into account, resulting in a failed setup procedure.

It's not easy to set up an environmental test chamber. During the setup procedure, there are a number of potential stumbling blocks. The worst-case situation is that the chamber is damaged or wrongly installed. We've put up a 5-step guide for installing test chambers to assist you to save time and money throughout the setup process.

1. Select the Best Installation Location

An environmental test chamber should be placed in a room with a flat floor that can support the chamber's weight while also being large enough to allow for optimal performance and maintenance. This space must also be free of airborne contaminants.

2. Take into account the outside temperature

Another factor to consider when deciding where to put a new environmental test chamber is the ambient temperature. When deciding on a temperature, keep in mind how much heat the chamber will dissipate during testing.

Install an air cooling system if necessary to guarantee appropriate chamber operation.

3. Pay Close Attention to the Electrical System

You'll also need to make sure the chamber has a properly adjusted power supply system, depending on the amount of performance it can reach. Make a note to examine the technical parameters of the chamber, since it may require particular connectors and cables.

You'll most likely be working with high-amperage wires, so prepare your lab ahead of time.

4. Make certain you have access to the water you require

There are two water supply connections to consider: the humidification system's water connection and the water condenser's water connection. This is especially true if your test chamber is water condensed but has an integrated water softener.

In this scenario, you'll need an external supply system for demineralized water as well as an additional water connection for the water condenser, which must produce water with certain properties to meet the technical requirements of your environmental chamber type.

5. Avoid Clogging by Taking Precautions

If your chamber has a recirculation system for the dehumidification water, you'll also need to install a water drainage system near the chamber. When the test specimen is unclean, this is a critical step to avoid the water drain being plugged.

The water can also be collected by allowing it to flow into a container.

Environmental Test Chambers Installed to NEMA Standards

The National Electrical Manufacturers Association (NEMA) establishes guidelines for all environmental test chamber setups, so double-check that your setup complies not just with your chamber's specs but also with NEMA's.

Otherwise, a poorly installed environmental test chamber might add to your laboratory's expenditures while also jeopardizing the quality of your test findings.